This article originally appeared in Issue 1 of The Campaigner. The issue is still available as digital download.

By Steven “Demo” Rohde | Edited by: Lauren Palenski

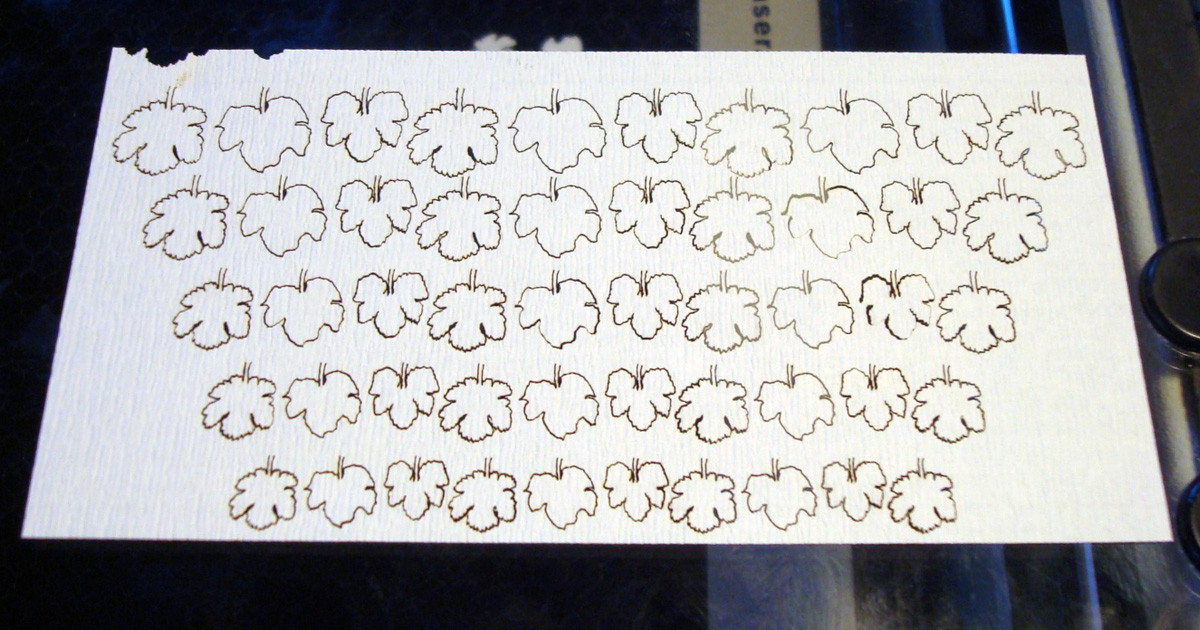

When I was first approached about doing this article I was excited to have the opportunity to talk about my passion. Sharing my knowledge on the subject of laser-cutting and getting more people interested in laser-cut gaming products is something I do regularly when talking with customers.

There’s so much to talk about, so where should I even start? The process of laser-cutting is easier to understand than it may sound right away. I could tell you about how the laser works in great detail, how electrons are pushed out into a higher orbit by pumping the laser medium full of energy, and when the electron tries to go back to its lower orbit a photon is created. Those photons are then collected in a mirrored chamber and then reflected towards the intended material where they start cutting. The heat a laser produces is a by-product from the oxidation of the material as the photons start a chemical reaction with the material they are slamming into.

Needless to say, that was a little technical. The number one thing to know about a laser is that it is a monochromatic stream of photons. All the photons are marching in step which is what gives the laser the ability to cut materials. The more wattage a laser has the thicker the material it can cut. At a previous job I worked with a 3,400 watt laser that could cut one inch thick cold-rolled steel. By focusing and adjusting the laser to the correct frequency for the material being used it cut anything from the thinnest of rice paper to a quarter inch piece of wood. All without burning or causing the delicate project to go up in flames.

One belief that I often have to dispel as a laser operator is that people think of it as a heat-ray. Personally I blame television, books and movies that always seem to have an evil villain trying to destroy things with their laser. I’m not angry at the way lasers have been portrayed mind you, I love a good sci-fi movie or book from time to time. But it is kind of like when I watch a lawyer based television show and then run to my friend Jim who does legal work. When I ask him “is that possible?” he just shakes his head and reminds me the show is on the “good lawyer’s” side. For all you budding mad scientists however, don’t be disheartened. If you could focus a powerful enough laser onto the surface of the moon you could actually raster (engrave) your likeness on it!

There are a large number of people in the war gaming hobby who are allergic to cyanoacrylic glues (aka super glue). Laser-cutting allows for a variety of materials to be used, such as wood which can be assembled with PVA glue. This means even kids can get into the fun of assembling a model without worry, with the added bonus of easy glue clean-up. The versatility of laser-cutting also means that a single machine can process a number of materials. For instance, at Demo’s Laser-Cut Designs we can process wood, Taskboard®, Matboard and backer board using one machine.

Article continues in Issue 01. The issue is still available as digital download.